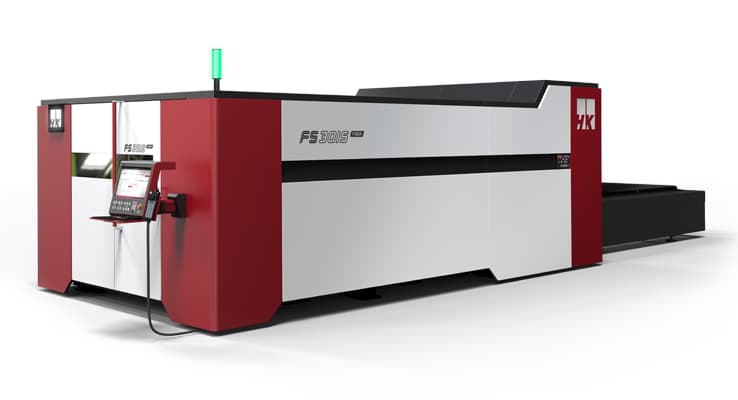

Fiber Laser Cutting Machine Italy

However, fiber lasers tend to be quite expensive. If you need a cheaper laser engraver, then you might consider using diode type lasers.

There are also options for engraving areas of 6.9"x6.9", 5.9'x5.9", 4.3", 4.3", 2.6"x2.6", and 4.3". You can choose one or more depending on your operational requirements.